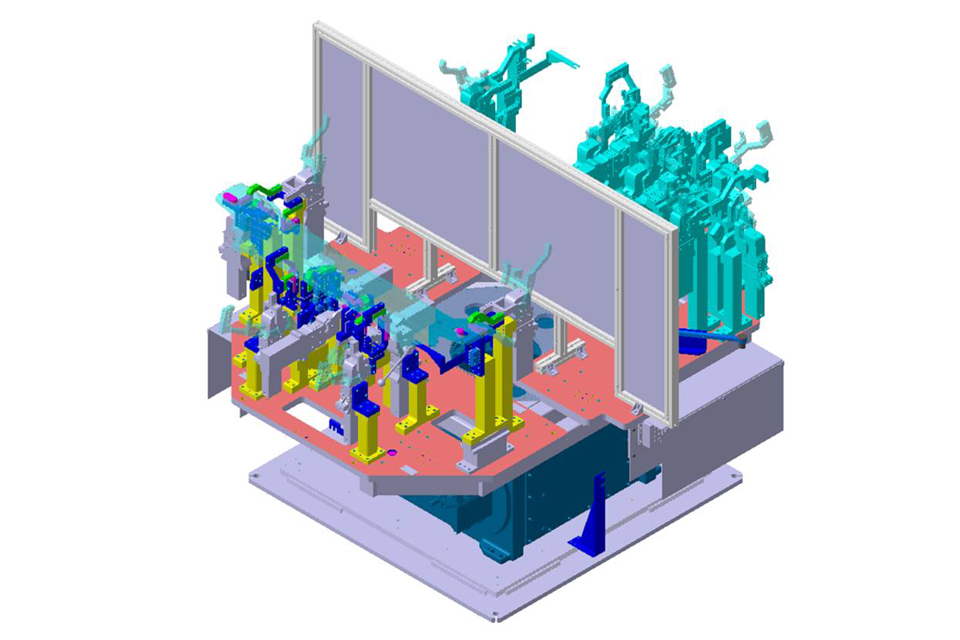

Welding Fixtures Design For Roof Lines of

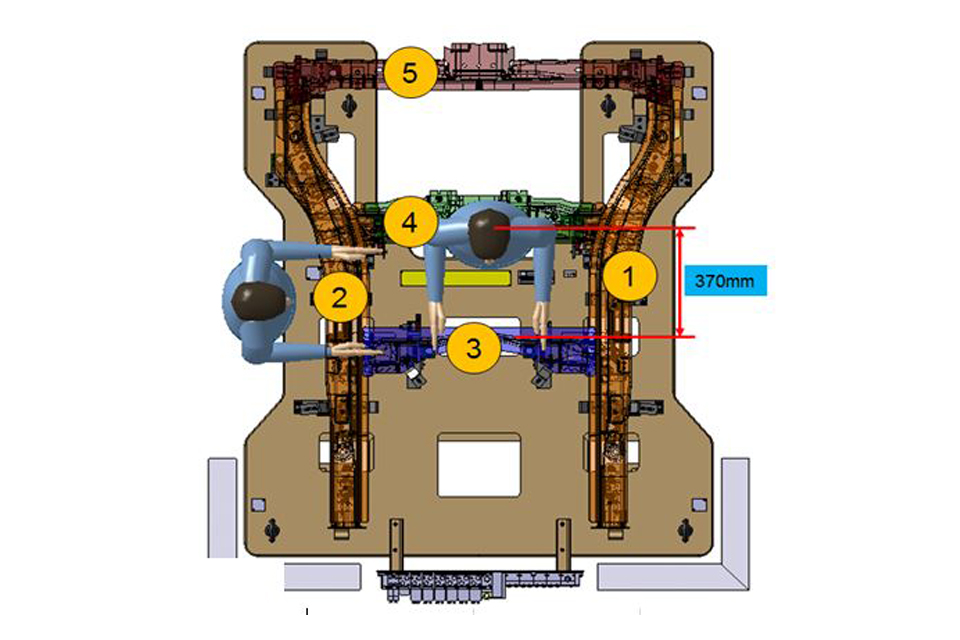

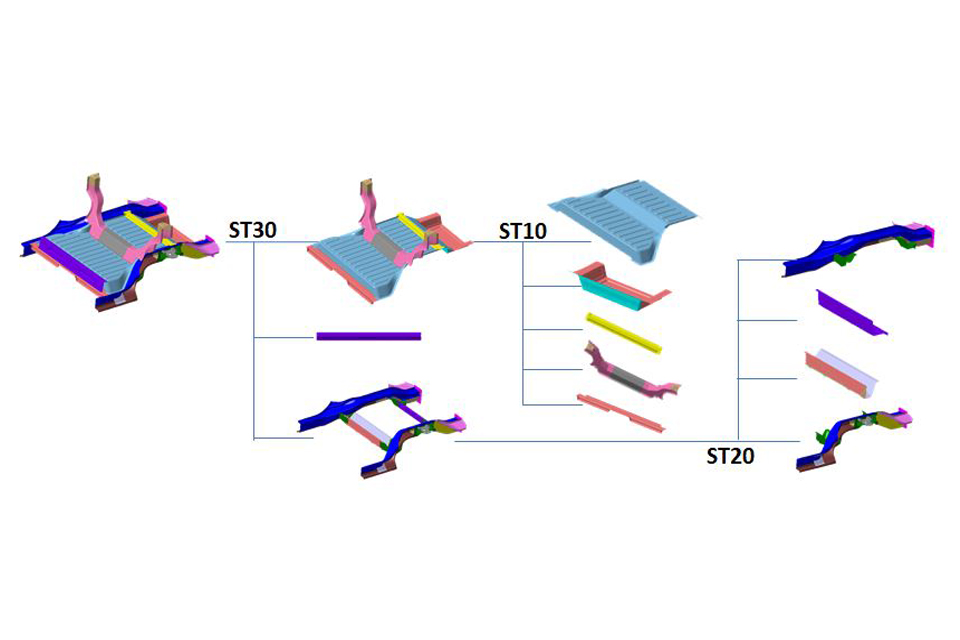

Introduction

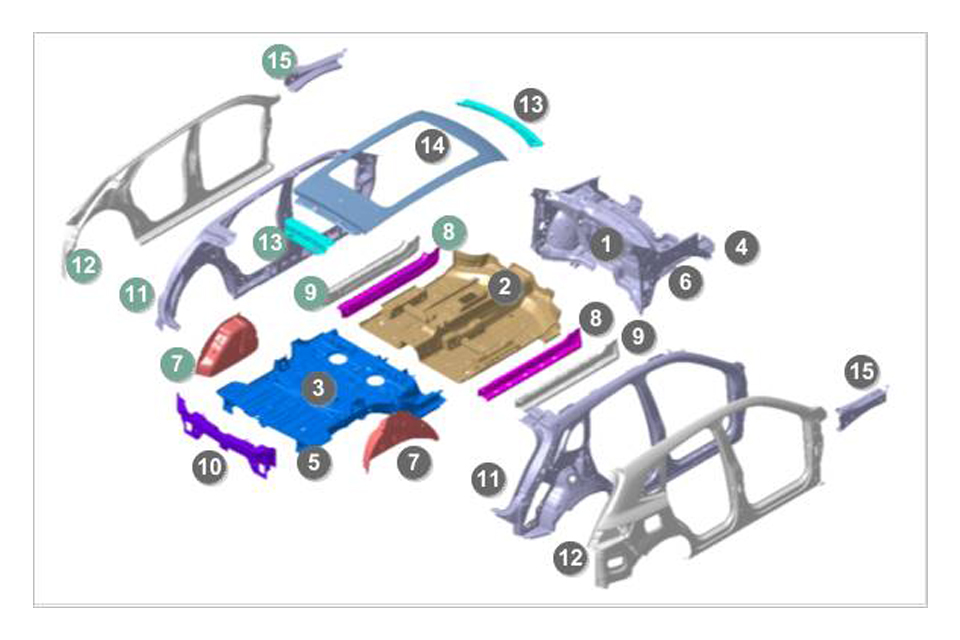

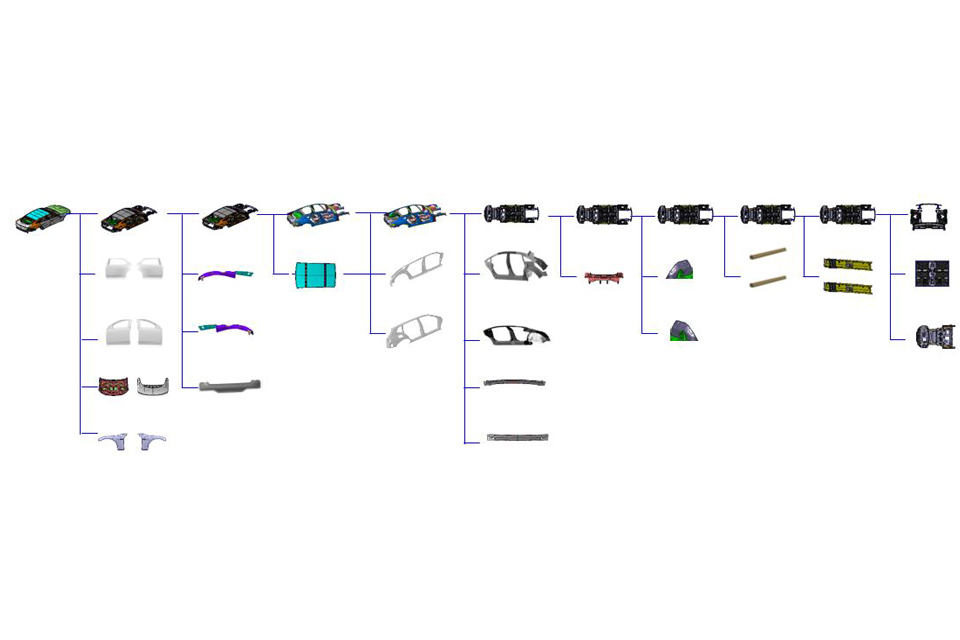

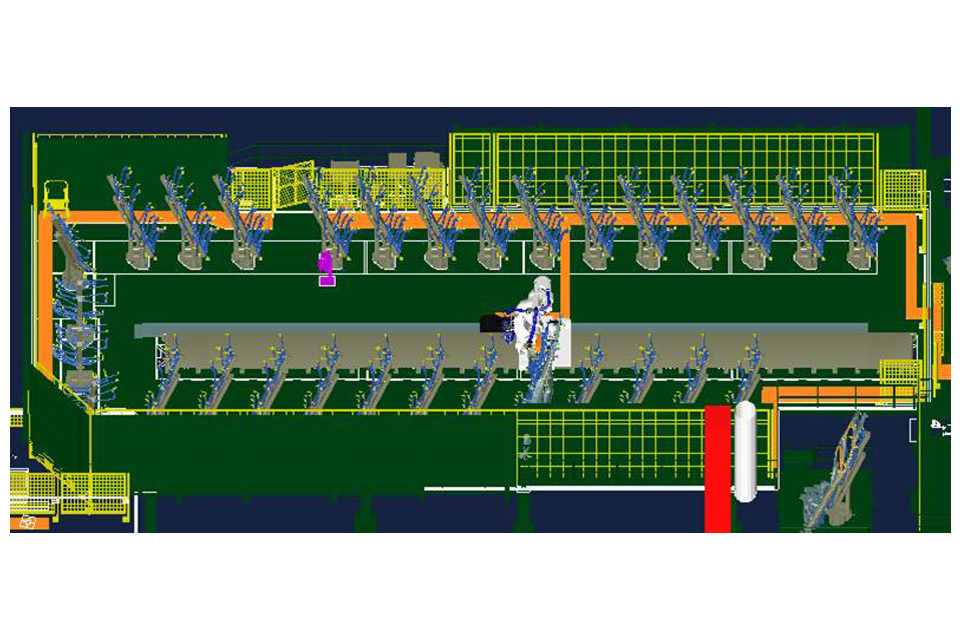

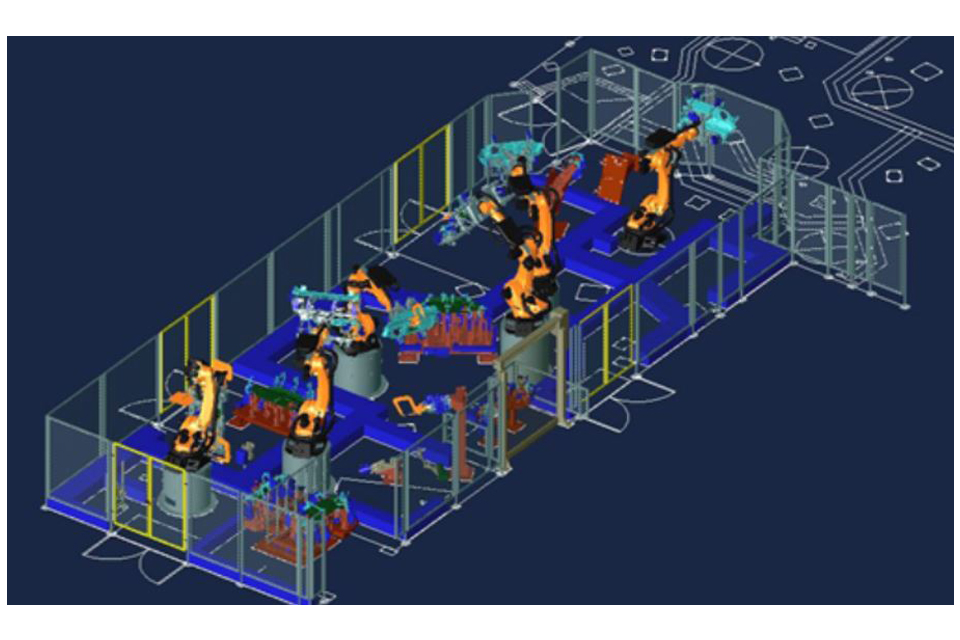

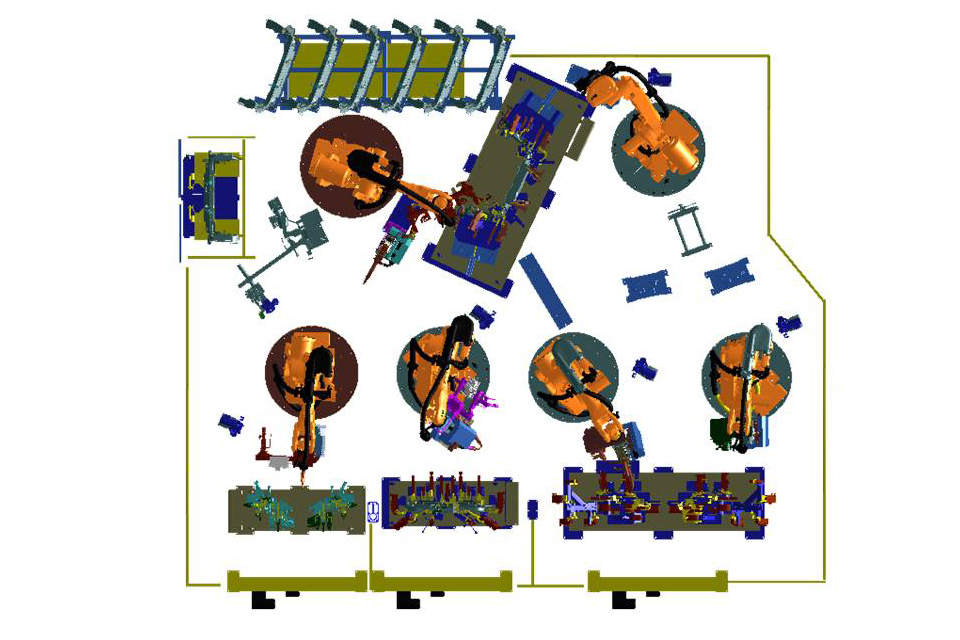

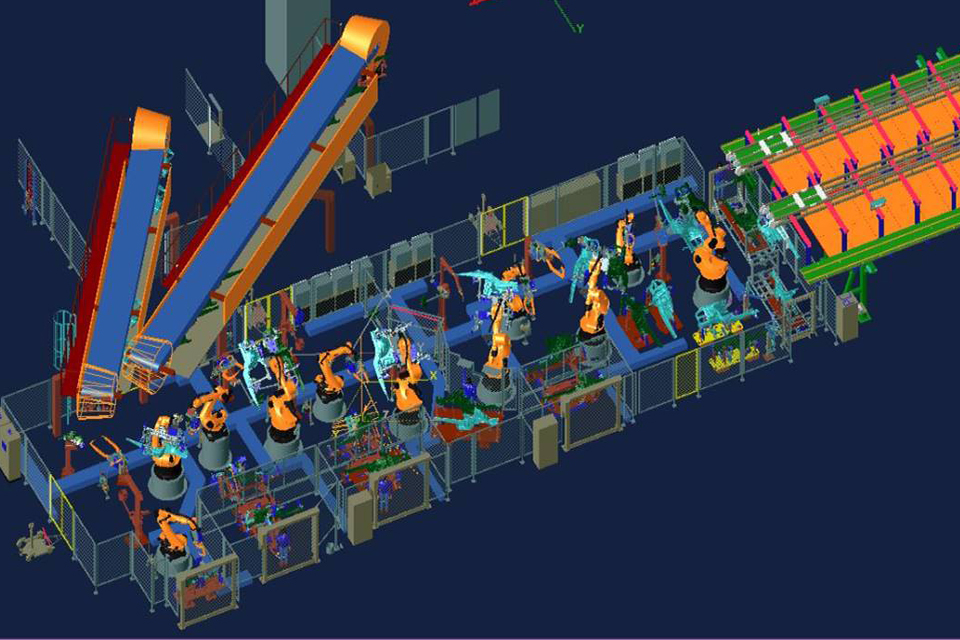

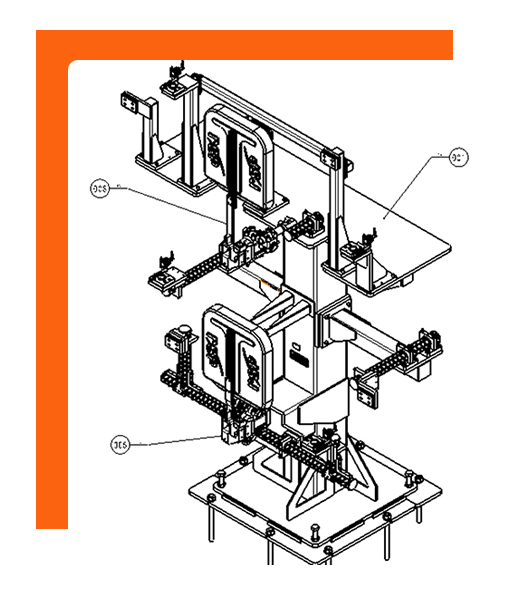

Scope of the work is to design the welding fixtures for Roof line. Cycle time study, Layout study, Concept Design of Various tools for 5 Variants, 3D Finish, 2D detailing, Drawing Released for Manufacturing.

Description

Completed the Concept Design, 3D finish and released the manufacturing drawings within the customer requested timeline. and within the budgeted hours.

Tools Designed

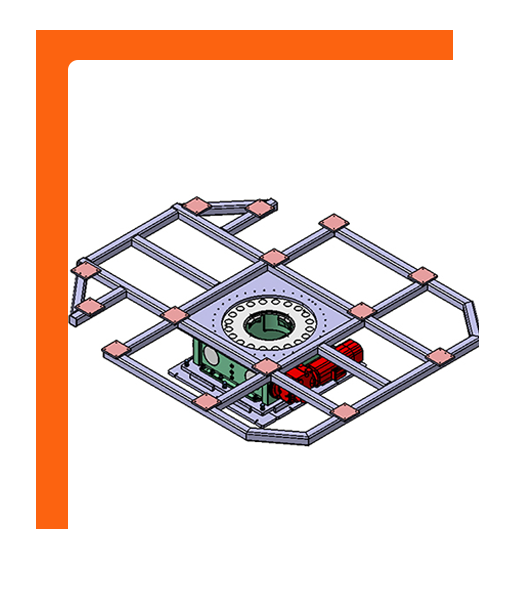

Geometric Tools (GEO), Respot tools, Grippers,Trolleys, Load Tables, Gripper stands ( Single & Dual), Glue gun stands, Welding gun stands, Turntable frames.

Software Used

CATIA V5

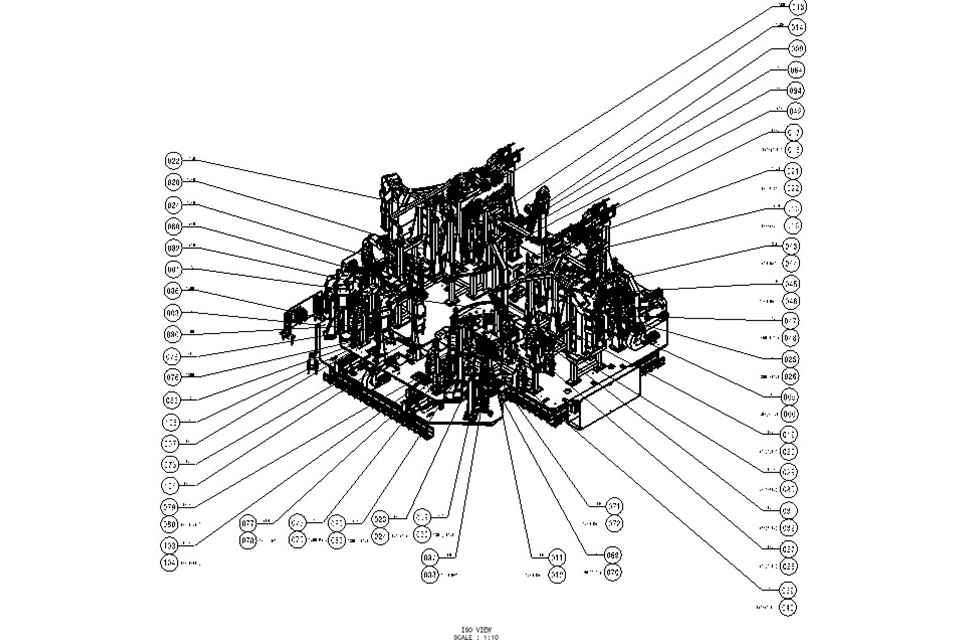

Manufacturing Drawing Creation

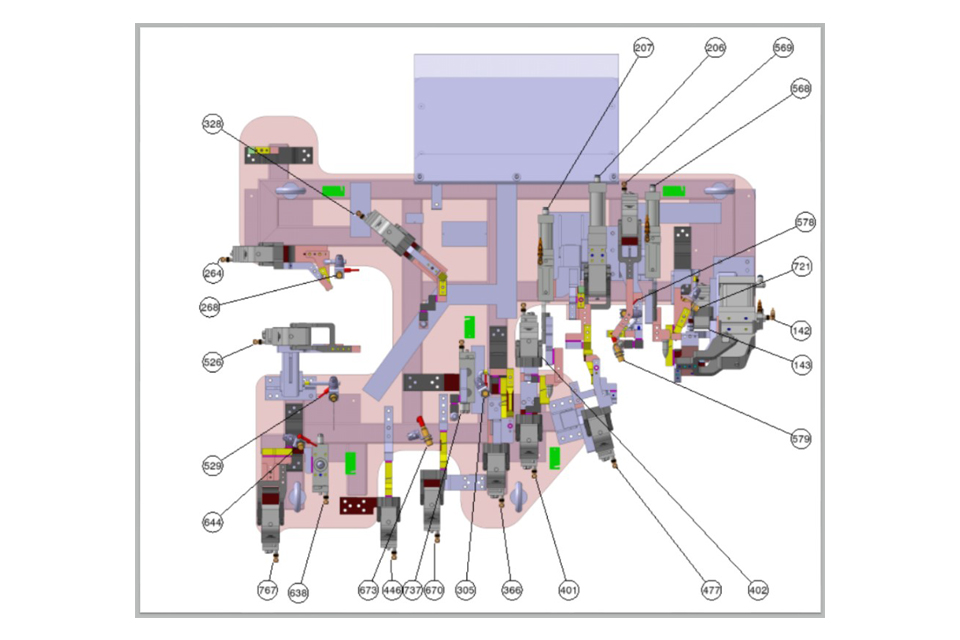

Introduction

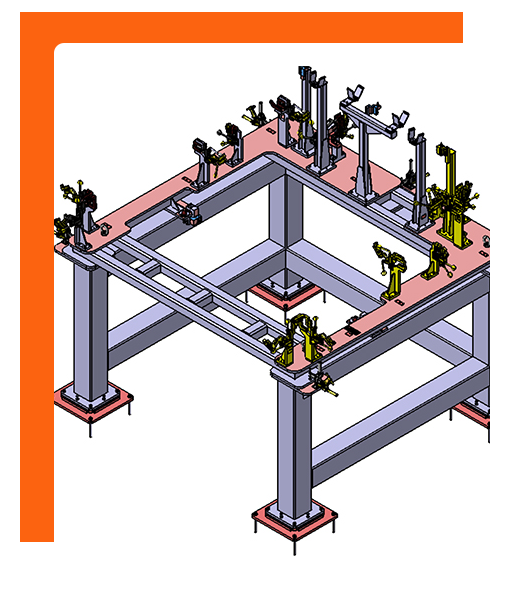

Manufacturing drawing creation for geo fixture.

Description

Completed the 2D Detailing and released the manufacturing drawings within the customer requested timeline and within the budgeted hours.

Software Used

CATIA V5

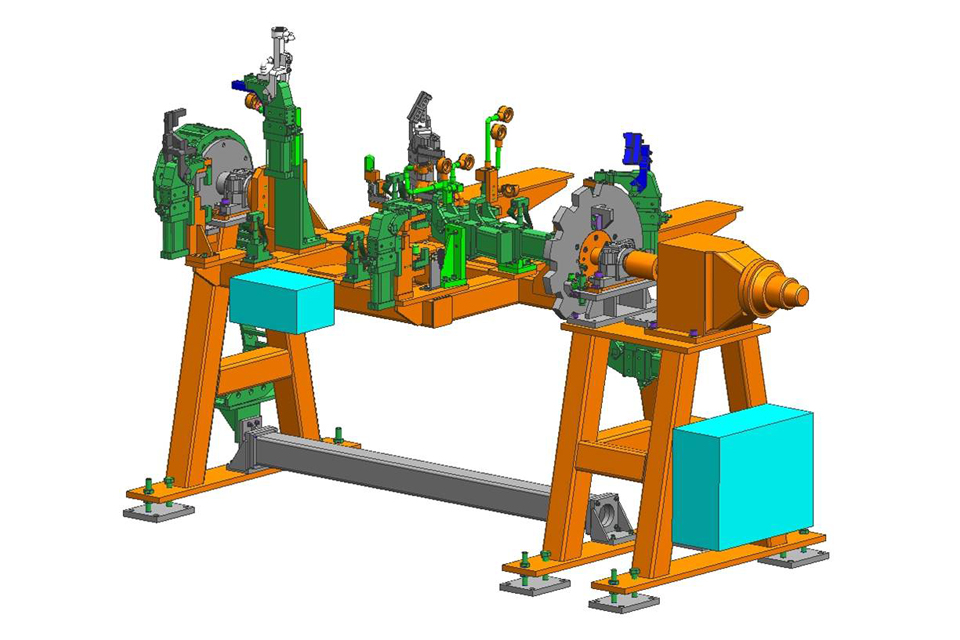

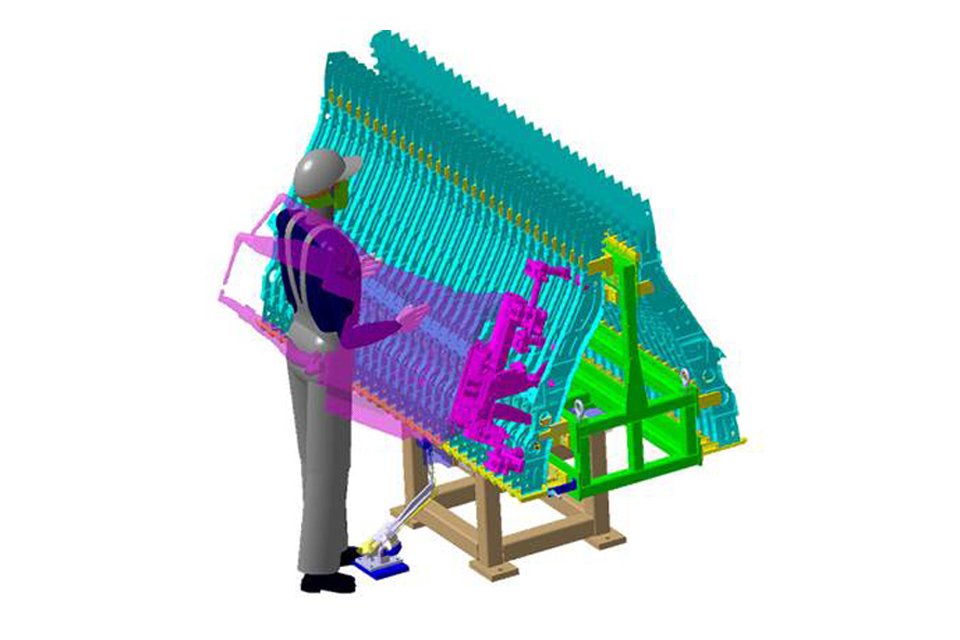

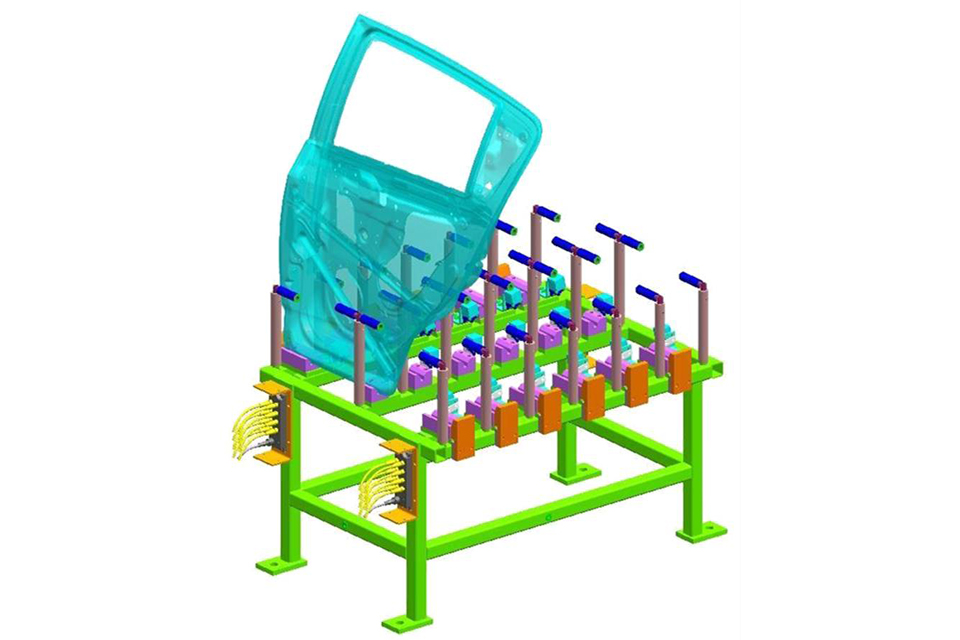

Welding Fixtures Design For Wheel House Panel

Introduction

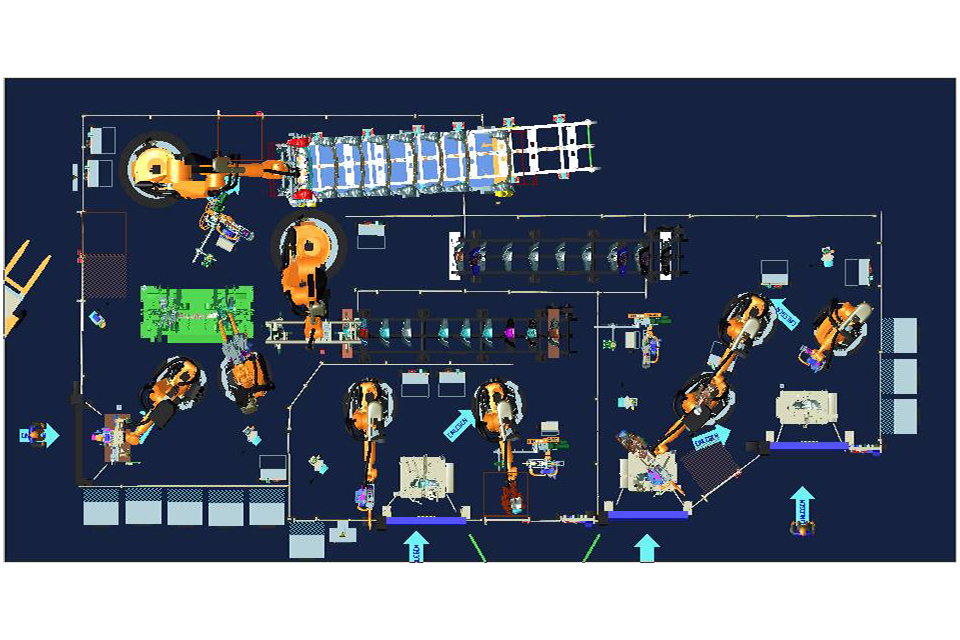

Scope of the work is to design the welding fixtures for Roof line. Cycle time study, Layout study, Concept Design of Various tools for 3 Variants, 3D Finish, 2D detailing, Drawing Released for Manufacturing.

Description

Completed the Concept Design, 3D finish and released the manufacturing drawings within the customer requested timeline. and within the budgeted hours.

Tools Designed

Geometric Tools (GEO), Respot tools, Grippers, Trolleys, Load Tables, Gripper stands ( Single & Dual), Glue gun stands, Welding gun stands, Turntable frames.

Software Used

Unigraphics NX11